BLOG

Zuschneidfelle: Its Importance in Modern Craft and Material Processing

The term has gained attention among professionals and hobbyists involved in material processing, crafting, and specialized production work. Originating from practical applications, represents materials prepared specifically for cutting, shaping, and customization. As demand for precision and quality increases, has become an essential concept in various creative and industrial fields.

This article explores the meaning, applications, benefits, and future relevance of in a clear and human-focused way.

Understanding the Concept of Zuschneidfelle

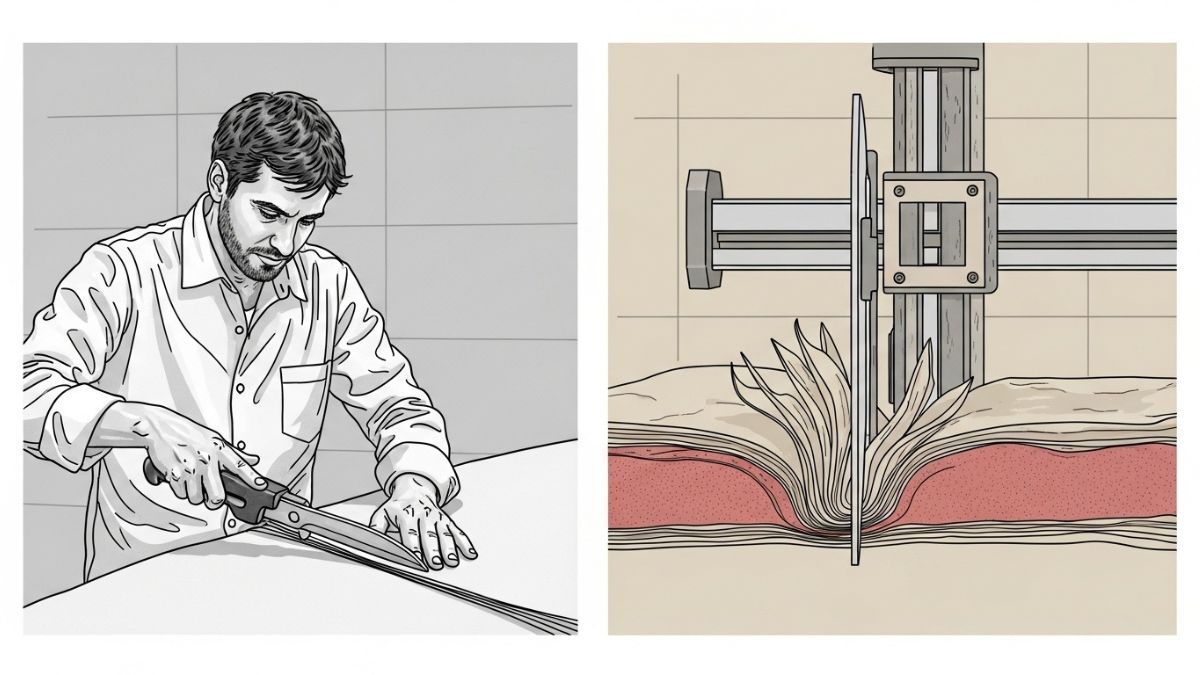

The concept of refers to materials, often leather or similar surfaces, that are prepared for precise cutting and shaping. These materials are selected and processed to ensure consistency, durability, and ease of handling during production.

is commonly associated with craftsmanship, where accuracy and material quality play a crucial role in the final outcome.

The Role of Zuschneidfelle in Craftsmanship

Craftsmanship relies heavily on reliable materials, and provides a dependable foundation for skilled work. Whether used in handmade goods or structured production environments, these materials support consistent results.

Artisans value for its balance of flexibility and strength, allowing for intricate designs without compromising durability.

| Craft Area | Use of Zuschneidfelle |

|---|---|

| Leatherwork | Precise cutting and shaping |

| Fashion Production | Consistent material quality |

| Upholstery | Accurate pattern creation |

| Custom Design | Flexible application |

Industrial Applications of Zuschneidfelle

Beyond craftsmanship, plays an important role in industrial settings. Manufacturers rely on prepared materials to streamline workflows and reduce waste. The consistency of supports automation and large-scale production without sacrificing quality.

This reliability makes it suitable for industries that require repeatable precision.

Why Zuschneidfelle Is Valued for Precision Work

Precision is a defining characteristic of . Materials prepared for cutting reduce errors and allow creators to focus on design rather than material limitations. This advantage is especially important in industries where accuracy directly impacts cost and performance.

The structured preparation of ensures predictable results.

Zuschneidfelle and Material Efficiency

Efficiency is a major benefit associated with . By using materials specifically designed for cutting, waste is minimized, and production timelines are improved. This efficiency supports both sustainability goals and economic considerations.

| Efficiency Factor | Impact |

|---|---|

| Reduced Waste | Lower material loss |

| Consistent Thickness | Improved accuracy |

| Easy Handling | Faster workflow |

| Predictable Results | Cost efficiency |

Sustainability and Zuschneidfelle

Sustainability has become increasingly important, and supports responsible material usage. Proper preparation allows for maximum utilization of each piece, reducing unnecessary disposal.

When sourced ethically, contributes to more sustainable production practices.

Zuschneidfelle in Custom Design Work

Custom design projects benefit greatly from due to its adaptability. Designers can modify patterns and dimensions with confidence, knowing the material will respond predictably.

This flexibility encourages creativity without compromising quality.

Quality Control and Zuschneidfelle

Quality control processes often rely on standardized materials, and meets this requirement effectively. Uniform preparation ensures that each piece behaves consistently during production.

This consistency is critical for maintaining brand reputation and customer satisfaction.

Future Outlook of Zuschneidfelle

The future of looks promising as demand for precision and customization continues to grow. Advancements in material processing and ethical sourcing are likely to enhance its value further.

As industries evolve, will remain a foundational element in quality-driven production.

Conclusion

The importance of lies in its ability to support precision, efficiency, and quality across multiple industries. From traditional craftsmanship to modern manufacturing, it provides a reliable foundation for creative and industrial success.

As production standards rise, continues to represent excellence in prepared materials.

-

TECHNOLOGY4 days ago

TECHNOLOGY4 days agoKhareenjoyceromana: Its Growing Digital Identity in Online Spaces

-

TECHNOLOGY4 days ago

TECHNOLOGY4 days agoWachappe: Its Growing Relevance in the Modern Digital World

-

TECHNOLOGY3 days ago

TECHNOLOGY3 days agoGlarklyHub: A Complete Guide to Understanding Its Digital Impact and Growing Popularity

-

TECHNOLOGY2 days ago

TECHNOLOGY2 days agoGlarklyHub: A Complete Insight Into Its Purpose, Digital Identity, and Online Growth

-

TECHNOLOGY2 days ago

TECHNOLOGY2 days agoAponeyrvsh: Its Concept, Digital Importance, and SEO Potential

-

TECHNOLOGY1 day ago

TECHNOLOGY1 day agoCjmonsoon: Its Meaning, Digital Presence, and Growing Popularity

-

TECHNOLOGY1 day ago

TECHNOLOGY1 day agoPlangud: Its Meaning, Usage, and Growing Digital Relevance

-

TECHNOLOGY2 hours ago

TECHNOLOGY2 hours agoGessolini: The Meaning, Digital Presence, and Growing Online Interest